Is it Worth Investing in Orbiter Channel Storage Systems For Your Warehouse?

High-efficiency distribution operations begin with intelligent technology that helps optimize and automate current processes. McMurray Stern’s channel storage with orbiter shuttle systems provides rapid material transport and quick access times, utilizing pallets, trays, cartons, or bins. When you invest in orbiter channel storage systems, you’re moving your warehouse towards innovative storage solutions to prepare you for future challenges. Read more about the orbiter shuttle components, functions, features, and technology integrations that are available.

Components of Our Orbiter Channel Storage Systems

The orbiter shuttle system works with channel storage to help streamline your warehouse or distribution operations. The system comprises of four key components: a channel vehicle, a control system, a docking station, and a power cap.

Orbiter Channel Vehicle

The channel vehicle is the heart of the system. It can move flexibly and intelligently through channel storage systems to pick up and drop off products as controlled.

Control System

The remote control enables simple operation for perfect handling. The user interface features easy-to-read icon buttons that make controlling the shuttle straightforward. In addition, the remote makes it easy to move the orbiter around the warehouse for persistent storage and retrieval.

Docking Station

The docking station prevents unauthorized entry into the aisle. The orbiter shuttle has hazard warning lights to show the unit is ready for operation. If there are any interruptions in the aisle, the shuttle will stop instantly to prevent any damage. There is also an emergency off switch that users can utilize if necessary.

Power Cap

The power cap is a patent-pending device that can be used to move the shuttle through the channel storage system without needing an external power source. The orbiter shuttle system can run for up to 16 hours of operation per battery charge.

Orbiter Channel Storage System Functions & Features

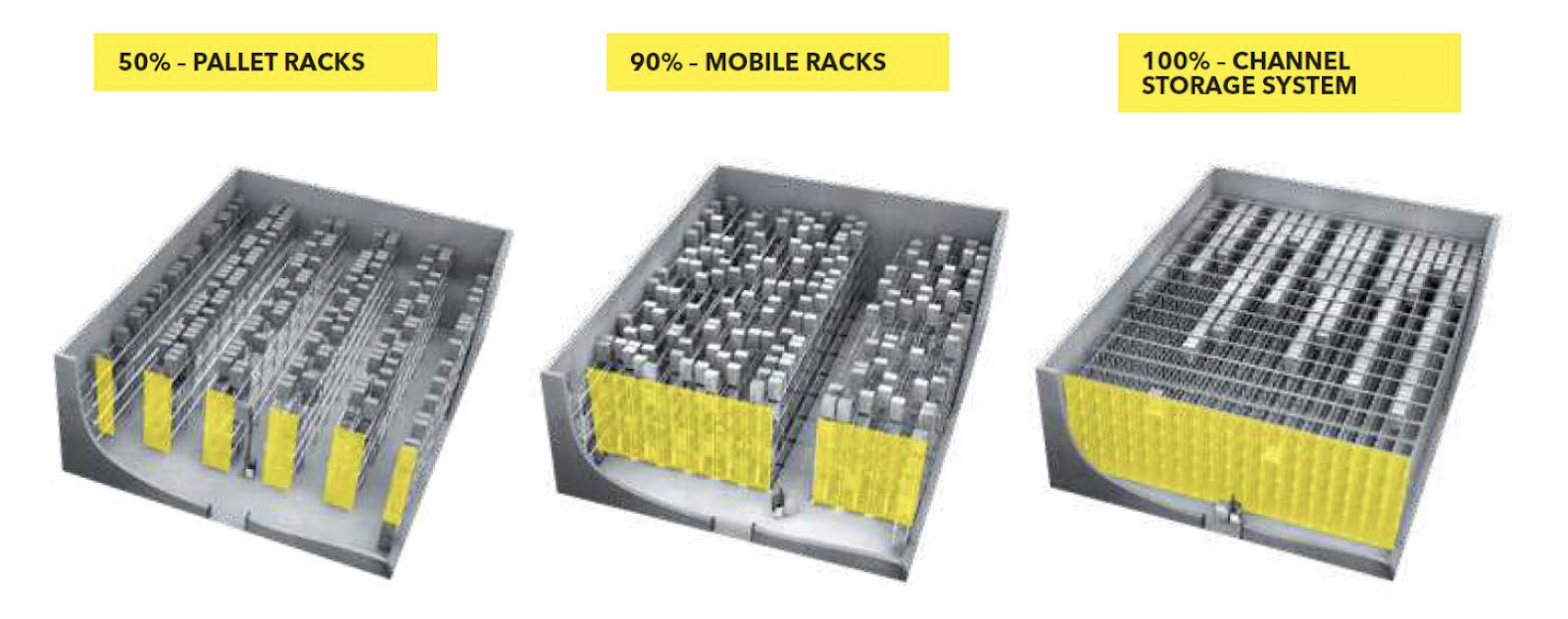

When investing in orbiter channel storage systems, warehouses typically see increased area utilization and 2x storage capacity gained.

Utilize 100% of your space with channel storage systems. The orbiter can be used with any conventional forklift or Automated Guided Vehicle (AGV) to safely and efficiently store and retrieve pallets. Additional features and functions include:

- Shuffle mode for the reorganization of channels as needed

- Inventory mode for improved inventory management

- High-performance Automated Storage and Retrieval Systems (ASRS) through channel storage shelving

- Smooth movement handling for sensitive goods

- Sustainable and economical operations

- Maximum flexibility, scalability, and space utilization

- Ideal for handling high volume, low SKU count

- Battery charging for up to 16 hours of operation per charge

- Optimize receiving and shipping operations

- Reduce labor and energy costs

- Ideal option for freezer and chill environments (suitable for the grocery industry)

- Quick build-out with an easy-to-use user interface

- Transfers SLR into storage channel

- Flexible load handling device

Inventory Management Installation Options

The way you stock your inventory matters. Our channel storage systems offer two ways of organized storage and retrieval – FIFO and FILO. When deciding which method to use, businesses must weigh the benefits and drawbacks of each design approach.

First In, First Out (FIFO)

A feature utilized when you need to handle the transportation of your newest stock first (i.e., perishable grocery goods or beverages that have an expiration date).

First In, Last Out (FILO)

FILO occurs when your oldest stock is used first. This inventory method is often used with non-perishable goods, as it helps prevent obsolescence (i.e., hardware supplies from last year would be used before lightbulbs were delivered yesterday).

Additional Storage Design Functions

Orbiter Channel Storage Picking Solutions

In addition to inventory control, many businesses choose to integrate a tunnel into their channel storage to streamline manual picking in the warehouse.

Cleaning

The lowest level of the channel storage systems is designed for easy cleaning functionality. Allowing full access to the channels from the floor, this design eliminates the need for a mezzanine.

Orbiter Channel Storage Security Measures

The channel storage system features a secure fence and ground approach strip to ensure high safety and damage prevention levels.

Technology Integrations

Our orbiter shuttle systems can connect to WMS and MFC software to improve inventory processes and user-friendly reporting features.

Implement Orbiter Channel Storage in Your Warehouse With McMurray Stern!

If you’re ready to improve your warehouse operations with an orbiter channel storage system, McMurray Stern is here to help. We offer a wide range of automated and static storage options that are customized to fit the specific needs of your business.

To learn more about our storage solutions, schedule a free consultation with one of our storage experts or give us a call at (562) 623-3000.

Recent blogs

Contrary to popular belief, Lorem Ipsum is not simply random text. It has roots in a piece of classical Latin literature from 45 BC